|

|

| |

HD Series Honeycomb Dryer

|

| |

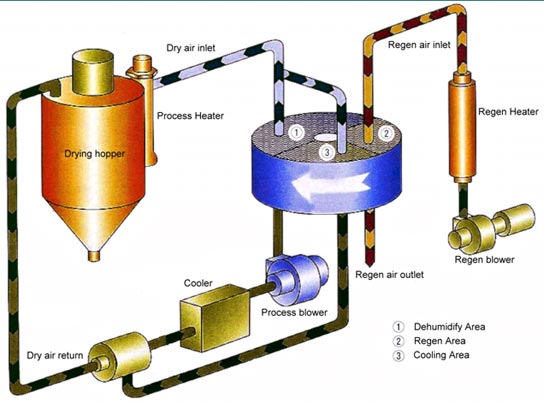

HD series honeycomb rotary dehumidifying dryer, suitable for hygroscopic plastic materials�� drying. The honeycomb rotor is applied for high-efficiency dehumidification

and supply dehumidified dry air with a dew point lower than -40�J~-60�J. The whole system is close looped design. Energy saving and prevent heat loss.

Feature:

|

1.

|

The honeycomb rotors are supplied from SEIBU GIKEN , made in Japan, very high quality.

|

|

2.

|

P.I.D. temperature controls for high accuracy and stable drying temperature.

|

|

3.

|

According to different materials�� characteristic, different type of dew point models - 40�J, -50 �J, - 60�J are available.

|

|

4.

|

Control error alarms.

|

|

5.

|

Safety functions for over heating, reverse phase protection.

|

|

6.

|

Low temperature drying will require optional second cooler.

|

|

7.

|

Blower delay off feature to prevent over heating of heater.

|

|

|

|

| |

|

| |

Honeycomb rotor process flow diagram

|

| |

|

| |

Plastics drying data

|

| |

|

MATERIAL

|

PE()Drying

Temp(°C)

|

Bulk

Density

(Kg/L)

|

Residence

Time(hr) |

Inital

Moisture

Content(%)

|

Residual

Moisture Content(%)

|

Airlow Requ.

(Nm3/kg/hr)

|

|

ABS

|

80

|

0.6

|

2-3

|

0.2

|

0.02

|

1.3~1.7 |

|

CA

|

75

|

0.5

|

2-3

|

1.0

|

0.02

|

1.8~2.5 |

|

CAB

|

75

|

0.5

|

2-3

|

0.8

|

0.02

|

2.2~2.5

|

|

CP

|

75

|

0.6

|

2-3

|

1.0

|

0.02

|

2.1~2.5

|

|

CP

|

150

|

0.6

|

4

|

0.04

|

0.02

|

1.3

|

|

PA

|

70~80

|

0.65

|

3-6

|

1.0

|

0.05

|

1.7~2.2

|

|

PBT

|

120~140

|

0.7

|

4

|

0.3

|

0.02

|

1.3~1.7

|

|

PC

|

120

|

0.7

|

2-3

|

0.3

|

0.01

|

1.3

|

|

PE

|

90**

|

0.6

|

1

|

> 0.01

|

> 0.01

|

1.3~1.7

|

|

PE

(40% block)

|

90

|

0.6

|

3

|

0.8

|

0.02

|

2.2~2.4

|

|

PEEK

|

150

|

0.6

|

3-4

|

0.4

|

0.02

|

1.3~1.7

|

|

PEI

|

150

|

0.6

|

3-4

|

0.25

|

0.02

|

1.3

|

|

PEN

|

170

|

0.85

|

5

|

0.01

|

0.005

|

1.7~2.5

|

|

PES

|

150~180*

|

0.7

|

4

|

0.8

|

0.02

|

1.4~1.7

|

|

PET(inj)

|

110~120

|

0.85

|

3-4

|

0.04

|

0.02

|

1.2

|

|

PET

(prefrom/

Extrusion)

|

160~180

|

0.85

|

6

|

0.08

|

0.005

|

1.7~2.5

|

|

PETG

|

60~70

|

0.6

|

4-6

|

0.5

|

0.02

|

1.7

|

|

PI

|

120~140

|

0.6

|

3

|

0.4

|

0.02

|

1.1~1.3

|

|

PMMA

|

70~100

|

0.65

|

3

|

0.5

|

0.02-

|

1.4~1.7

|

|

POM

|

95~110

|

0.6

|

3

|

0.2

|

0.02

|

1.2~1.7

|

|

PP

|

90

|

0.5

|

1

|

> 0.01

|

0.02-

|

1.3~1.7

|

|

PPO

|

110~125

|

0.5

|

2

|

0.13

|

0.04

|

1.3~1.5

|

|

PPS

|

140~150

|

0.6

|

3-4

|

0.1

|

0.02

|

1.3

|

|

PS

|

80**

|

0.5

|

1

|

> 0.01

|

0.02

|

1.1~1.3

|

|

PSU

|

120~170

|

0.65

|

4

|

0.3

|

0.02

|

1.3~1.4

|

|

PUR

|

89~90

|

0.7

|

3

|

0.2

|

0.02

|

1.8~2.0

|

|

PVC

|

70**

|

0.5

|

1

|

0.1

|

0.02

|

1.1~1.5

|

|

SAN

|

80

|

0.5

|

2-3

|

0.1

|

0.05

|

1.2~1.5

|

|

SB

|

80

|

0.6

|

2

|

0.2

|

0.05

|

1.2~1.5

|

|

TPE

|

105

|

0.7

|

3

|

0.1

|

0.02

|

2.1

|

|

| |

|

| |

|

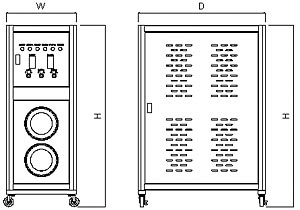

Specifications�G

|

|

Model

|

HD-050

|

HD-100

|

HD-200

|

HD-300

|

HD-400

|

HD-700

|

HD-1000

|

|

Process air flow

(M3/Hr)

|

50

|

100

|

200

|

300

|

400

|

700

|

1000

|

|

Process heater (KW)

|

3

|

6

|

10

|

10

|

15

|

25

|

35

|

|

Process motor(KW)

|

0.5

|

0.85

|

1.9

|

2.6

|

3.7

|

6.3

|

7.5

|

|

Regen heater (KW)

|

2

|

4.5

|

4.5

|

6

|

8.5

|

15

|

18

|

|

Regen motor

|

0.2

|

0.2

|

0.5

|

0.85

|

0.85

|

2.6

|

3.7

|

|

Process DUCT OD (mm)

|

38.1

|

63.5

|

63.5

|

76.2

|

88.9

|

114.3

|

127

|

|

Regen DUCT OD (mm)

|

38.1

|

50.8

|

50.8

|

50.8

|

63.5

|

76.2

|

88.9

|

|

H(mm)

|

1455

|

1455

|

1455

|

1755

|

1755

|

2055

|

2055

|

|

W(mm)

|

550

|

550

|

550

|

750

|

750

|

1150

|

1150

|

|

D(mm)

|

800

|

800

|

1000

|

1150

|

1150

|

1500

|

1500

|

|

Weight (KG)

|

180

|

200

|

250

|

300

|

350

|

500

|

630

|

|

Standard Power supply is 220V/3P/60Hz. If other specifications required, please advice before order.

Standard process temperature is 120�J. Process temperature over 120�J is optional.

|

|

| |

|

| |

Options

|

1.

|

Touch Panel

|

|

2.

|

170°C Process temp

|

|

3.

|

Dew point display

|

|

4.

|

Heater on hopper |

|

5.

|

Cyclone filter |

|

6.

|

Auto-clean filter |

|

7.

|

Plasticizer Filter |

| 8. |

Secondary Cooler |

|

|

|

| |

|

| |

|

| |

|

| |

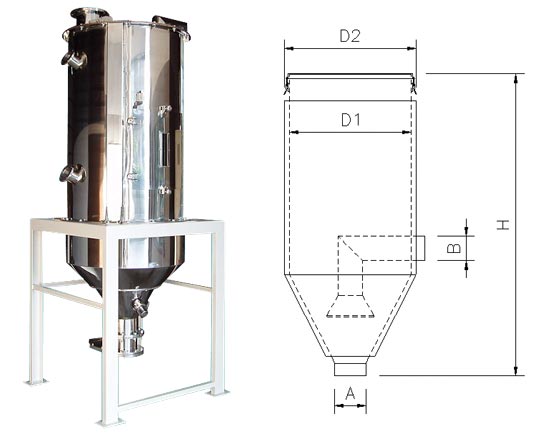

STAINLESS STEEL DRYING HOPPER

|

| |

Specifications

|

| |

|

Model

|

NPH-50

|

NPH-100

|

NPH-200

|

NPH-300

|

NPH-400

|

NPH-800

|

NPH-1000

|

|

Hopper Capacity (KG)

|

50

|

100

|

200

|

300

|

400

|

800

|

1000

|

|

D1��( mm)

|

420

|

545

|

650

|

700

|

860

|

880

|

960

|

|

D2��(mm)

|

470

|

595

|

700

|

750

|

910

|

930

|

1010

|

|

H(mm)

|

1200

|

1400

|

1750

|

2000

|

2150

|

3000

|

3300

|

|

A Material outlet (��mm)

|

50.8

|

50.8

|

63.5

|

76.5

|

76.5

|

101.6

|

101.6

|

|

B Process air duct (��mm)

|

38.1

|

63.5

|

63.5

|

76.2

|

88.9

|

114.3

|

127

|

|

Weight

|

65

|

115

|

150

|

165

|

195

|

300

|

350

|

|

|

| |

- Hopper Capacity base on material bulk density 0.65g/cm3�C

- If special specifications required, please advice before order.

- Hopper interior finish 200 mesh polished.

- If level switch mounting hole or flange required, please advice before order.

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|